Increasing the value and demonstrating responsible production of by-products

This InFocus Webinar provided insights into the latest practices on the sourcing, traceability, production and utilisation of by-products, with speakers Arnt Ove Kolås (COO Feed, Pelagia), Emily McGregor (Fisheries Manager, MarinTrust), and moderator Brett Glencross (Technical Director, IFFO)

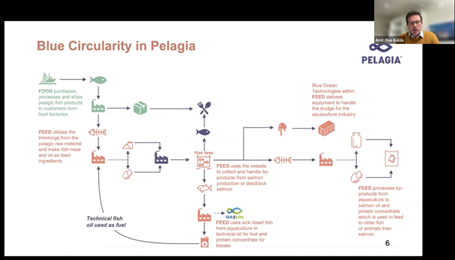

Arnt Ove Kolås opened by noting that Pelagia is aiming to use 100% of the fish, in order to create value for customers, fishermen, and vendors through the utilisation of by-products. Around 30% of Pelagia’s fish is directly landed for human consumption, and 70% is for marine protein meal and oil production. Production from by-products goes into Pelagia’s feed division, with the company also producing marine protein, marine oil, Omega- 3 oil (concentrates and pharma ingredients), and non-marine ingredient products. Using 100% of the fish means utilising all parts of the fish production process, from trimmings (from both wild caught and aquaculture), to the silage and sludge from aquaculture (taken from under the pens). “To achieve maximum efficiency and interconnectivity is a core part of Pelagia’s strategy with food and feed operations located on the same site. It is expensive but costs are saved from reducing transportation between factories” Kolås stated. By-catch is a key source for Pelagia’s by-products, but aquaculture by-products are growing fast.

New value-added products

Regarding increasing the availability of sustainable raw material, Pelagia is working to create new value-added products from the production process, creating more by-products for the marine ignredient industry, while also increasing the value of the meal and oil. Examples of innovation include making new products from the ash and fish skin, making more high protein meal and specialised ingredients like ketoloic acid and collagen. Ketoloic acid is a great example of a value-added product as it helps farmed salmon retain omega-3 in their own cells, actually improving the efficiency of utilisation of the omega-3 from their feed. Another example of reducing waste and adding value, is with the increase of production on board vessels, with fisherman now seeing the value mackerel trimmings. “We believe that the sum of the different parts of the fish in value creation is larger than the whole fish itself; all these products must have a business case and be financially viable, so efforts are targeted.”

Demonstrating responsible sourcing and traceability

Having covered the growing use of by-products, MarinTrust’s Dr Emily McGregor provided an overview on how companies can achieve certification and prove that these marine ingredient products are both responsibly sourced and produced. With around 50% of global marine ingredient production certified under MarinTrust, certificate holders can demonstrate their commitment to responsible sourcing, responsible traceability, and responsible production of marine ingredients. In terms of raw material sources covered by MarinTrust, they are divided into two groups, wild caught which directly used by fishmeal and fish oil plants, and by-products (trimmings) from human consumption processing that are sent to fishmeal and fish oil plants as a means of valorising the waste streams from human food production.

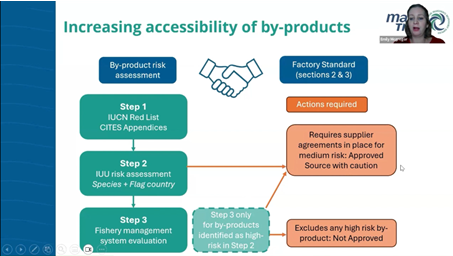

By-product production is a much more complex and a very diverse process, along with the supply chain that underpin them., They are fast growing with about 40% of marine ingredients today coming from by-products. MarinTrust’s Factory Standard is working to provide assurance that these by-products are responsible and coming from either a responsibly managed fisheries or specifically reducing the risk of illegal, unregulated and unwanted fishing production. “With 80 different wild caught species, from 180 stocks, already being utilised as by-products under the MarinTrust Standard, there is a lot of scope for even more by-products, particularly from aquaculture species. Under the third-party model that we operate, certification bodies are accessing over 300 by-products from over 100 factories globally.” The most common species that by-products are coming from are tuna, mackerel, herring and haddock, saithe, and cod. With both market demand and expectations growing, the required information on by-products, from the species’ name to where it was caught and who caught it, can be missing or even lost during processing for human consumption. MarinTrust focuses on the fishmeal and fish oil factory, and is working to deliver the expectations being passed down from the other end of the value chain, from consumers and retailers.

“Fishmeal and fish oil factories are required to collect a lot of information to maintain the evidence base to prove both the responsible sourcing and production of their ingredients. It requires a lot of work to maintain your supply, your suppliers, making sure that you're monitoring them and managing your due diligence. It requires investment in your quality management systems and your production system. It is not simple and certification needs to be transparent, it needs to be documented consistently and credibly through throughout the process, ensuring that the information flows through the supply chains.”

Approved by-products

To be an approved by-product, MarinTrust requires an evaluation of the source raw material to match what it defines as a responsibly sourced by-product. If not approved, work needs to be done before the by-product can be used in certified production, such as improving the source fisheries. Version 3, the latest version of the MarinTrust Factory Standard, is expected to enable more by-product-sourced marine ingredients to be audited and more fish to be third party assessed. It aims to reduce the complexity and introduces a risk-assessment framework for by-products, which is part of a ‘toolkit’ on due diligence, and a step-by-step process that checks IUU indices, endangered species lists and fisheries management system before approval. The process works with the producer to help mitigate risk and implement traceability. “A series of Key Data Elements (KDEs) from the life cycle have been identified (such as species name, flag state, and information supplier) to get traceability in place with key practical information to be delivered further down the value chain. Traceability provides the key information for the market to have confidence in a company’s sourcing” McGregor stressed.

In conclusion, Kolås added that MarinTrust’s Version 3 requires a lot of effort from the producers to meet those high expectations from the value chain: “At Pelagia we are providing feedback to MarinTrust to continue to drive improvements. In order to have complete traceability, you need to have control in each step and the information needs to be digital”. McGregor added that we also need to ask why we need a piece of information and make it simple, reasonable and practical to gather. The information needs to be interoperable with technology that allows information sharing down the value chain.

Watch the full recording below